WHERE DO BURLS COME FROM?

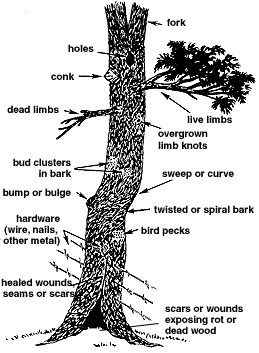

Trees are just like people in that there are many parts to them as well as many things that can impact their appearance – some genetics, some environmental, some cause by age and disease. Woodworkers and turners have a particular interest in those parts that are refered to as “burls”. From the outside they look like moles, or growths on the tree, but they are considered precious jewels for woodturners.

Burls can form on any species of tree and anywhere on the tree including the roots and the sides of the tree.

However, they often grow when the tree is undergoing some stress, whether it is an injury, virus, or fungal infection. When the tree’s growth hormones are disrupted it produces an unusual growth or density of cells. These growths are filled with small knots from dormant buds that create beautiful textures in the wood.

The burls that form can be small of become quite large in diameter. A burl can take as much as 30 to 40 years to reach it’s full size and beauty. During this time, the intricate patterns and beautiful colors are enhanced.

WHAT ELSE CAUSES BURLS?

In 2012 Kevin Smith, a plant physiologist at the U.S. Forest Service’s Northern Research Station published a piece on burl biology in the newsletter of the Massachusetts Tree Wardens’ and Foresters’ Association. He noted that:

“The crown gall bacterium is responsible for many burls (although many are too small for woodturning). That common bacterium is especially interesting, said Smith. It carries within it a little extra DNA, called a plasmid, which infiltrates the tree’s genetics. The plasmid prompts the tree to make special amino acids and growth regulators to produce the burl, which apparently is the preferred habitat for the bacterium. The bacterium that started the process can be long gone by the time the burl is of any size,” he said.

“Burls are occasionally associated with dormant buds, but even that does not explain why they get ‘turned on’ here and not there. Burls don’t seem to do much harm to the tree or shorten its life, said Smith. The xylem, twisted and contorted though it is, still seems to do its job of transporting water and nutrients. The vessels are still working and there’s still starch storage in the healthy outer parts of the burl, so it’s capable of normal function, though I’m sure that function is diminished.”

TURNING BURLS ON A LATHE

Burl wood is hard to work with hand tools. The grain variation is twisted and interlocked, causing it to chip easily. This “wild grain” makes burl wood extremely dense and resistant to splitting. These properties make it valued for bowls, mallets, mauls and handles of hammering chisels and driving wooden pegs. Each one is unique in its’ shape, pattern, color and texture. It is the job of the turner to bring this natural phenomena to the full potential of its’ beauty.

WHERE TO LEARN HOW TURN BURLS

The natural edge burl class at the Florida School of Woodwork is all about, bringing out the beauty in a unique and challenging piece of burl by turning it and texturing, carving and adding to the natural surface with color enhancements.

This is where you will learn the secrets of turning the cap and slab pieces and using the curves and valleys of the burl surface to make platters and bowls that will be the talk of the town.

Every single burl whether it is the cap or the slab cut will evolve differently from the one before.

You will discover the possibilities of color and textures that enliven the surface and you’ll also learn how to incorporate metalic elements to the burl, blending natural and man-made surfaces together in one beautiful artistic creation.