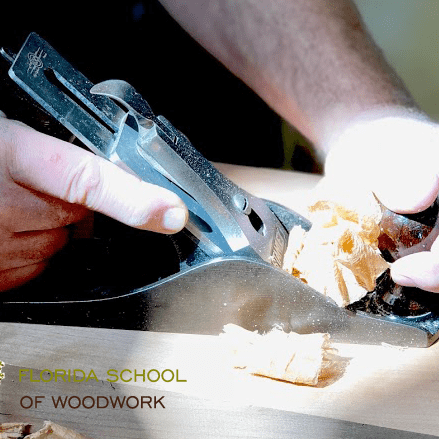

Why Do You Need Handplanes?

Learn about the parts of a hand plane and why you need them in your workshop

Why do you need hand planes? Well let me tell you a story. We had a workshop where I spent my childhood, but it was in a basement that seemed to be perpetually flooded. I spent a lot of time there, gathering wood scraps and straightening bent nails to use on my creations. One day, I spotted an old hand plane on a shelf. I had only seen my dad use it once or twice. I grabbed it and put it to the wood. I pushed the plane, but it stuck there. It didn’t move. So I applied more muscle and finally got it to skate across the wood. But that was it. No shaving. No progress. Nothing. I put the hand plane back on the shelf and forgot about it.

One day at Christmas decades later, my dad showed up at our family gathering, and held out a paper sack and said, “I found these in the shop. I thought you might be able to get some use out of them.” Inside was a No. 4-1/2 Stanley smoothing plane and a No. 78 duplex rabbeting plane. I remembered my first and last experience with that hand plane in dad’s basement shop and I thought, “What am I supposed to do with these?”

I was determined right then and there to figure out how to restore these old planes to their former glory. I spent hours on the internet researching how to tune a hand plane. I took the planes apart down to the last screw. I cleaned and polished every piece. I sharpened the iron the best I knew how using wet/dry sandpaper on a glass plate. It could shave the hair off of my arm, so I figured it was sharp enough!

I carefully reassembled the plane, heeding the advice I had found online for setting the cap iron and iron depth. Finally, the moment came to put the iron to wood. I carefully adjusted the iron and took a pass over the edge of a scrap piece of 2×4. I was shocked. Instead of chattering across the wood, the plane took a thin shaving that curled up, leaving a glass-smooth surface on the wood.

That moment changed my woodworking forever.

I realized how useful a hand plane is in the workshop. Here are some of the things that hand planes can do:

- Size workpiece to precise width, length, and thickness

- Quickly remove saw marks and burning

- Fine-tune a joint for a perfect, gap-free fit

- Flushing the faces of rails and stiles on an assembled door frame

- Trimming shelf edging flush

If you in the market to start buying hand planes here are my recommendations in order of importance:

- No. 3 or No. 4 Smoothing Plane

- Low-Angle Block Plane

- No. 5 Jack Plane

- Shoulder Plane

You can certainly restore hand planes from auctions, yard sales, and flea markets. If you’d rather start your collection with new hand planes, you can order them from Lee Valley and Woodcraft. These vendors offer discounted pricing to the students of the Florida School of Woodwork.

The Florida School of Woodwork has scheduled an evening class that will show you how to restore a hand plane if you’re interested in joining me. Whether it’s grandpa’s old plane or a newer one you can’t seem to get to work the way it should, bring it to this class. I’ll walk you through the steps of cleaning it and tuning it for the best results. You’ll soon realize what you’ve been missing in your woodworking.

Or if you’ve got a plane and you don’t know how to use it check out our upcoming joinery class.